Significance of Product & Analysis Testing at Airflo Sciences

At Airflo Sciences, the significance of Product and Analysis Testing resonates strongly in our commitment to quality assurance and innovation. Recognizing the pivotal role these testing processes play, we prioritize precision and thorough examination to ensure products meet rigorous standards.

Quality Assurance

Testing products ensures they meet specified standards and comply with regulatory requirements. It helps maintain consistent quality, reducing the risk of defects or substandard goods reaching the market.

Consumer Safety

For products intended for human use or consumption, testing ensures they are safe and pose no harm to consumers. This is crucial in industries such as pharmaceuticals, food and beverages, and consumer goods.

Compliance with Regulations

Many industries are subject to strict regulations regarding product composition, labeling, and safety standards. Product and analysis testing are essential to ensure compliance with these regulations, avoiding legal issues and potential fines.

Innovation and Development

Testing is integral to the research and development process. It helps identify areas for improvement, assess the performance of new materials or formulations, and contributes to innovation within industries.

Process Optimization

Analysis testing can be applied not only to finished products but also to various stages of production. This helps in optimizing manufacturing processes, identifying inefficiencies, and enhancing overall production quality.

Key Aspects of Product & Analysis Testing

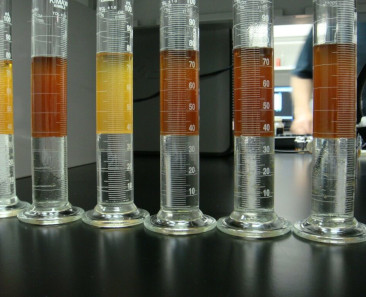

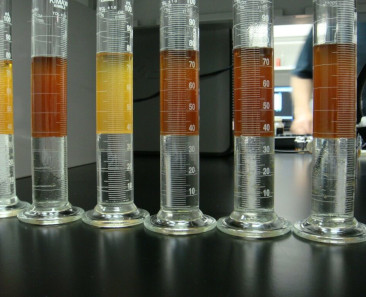

Composition Analysis

Composition analysis is a fundamental aspect of Product and Analysis Testing, involving a comprehensive examination of the chemical and physical makeup of products. This analytical process aims to ensure that products align with specified standards and adhere to regulatory requirements. Through detailed assessments, analysts identify and quantify key ingredients, verifying their presence and concentration within the product.

Quality Control

Quality control is a crucial facet of Product and Analysis Testing, focusing on the overall assessment of finished products to ascertain their adherence to predefined criteria and established quality standards. The objective is to verify that products are free from defects, consistently meet specifications, and maintain a high level of quality throughout the manufacturing process.

Safety Testing

Safety testing is an essential component of product analysis, particularly for items intended for human use, consumption, or interaction. This facet involves a thorough evaluation to identify potential health and safety hazards associated with the product. By conducting rigorous safety assessments, analysts ensure that products meet stringent safety standards.

Performance Testing

Performance testing plays a key role in assessing the functional capabilities of products. This aspect of analysis aims to verify whether products meet or exceed performance expectations in real-world conditions. Evaluations may include testing for durability, reliability, and overall effectiveness to ensure optimal performance for end-users.

Microbiological Testing

Microbiological testing involves the identification and quantification of microorganisms such as bacteria, fungi, and viruses present in products. This aspect is particularly relevant in industries like food and pharmaceuticals, where maintaining microbial safety is critical. Rigorous testing protocols help ensure products meet stringent microbiological standards.

Environmental Impact Assesment

Environmental impact assessment is a holistic aspect of Product and Analysis Testing that extends beyond the product itself to evaluate the environmental implications of manufacturing processes. This involves analyzing factors such as energy consumption, emissions, and waste generation to promote sustainable and environmentally responsible practices.

Regulatory Compliance

Ensuring regulatory compliance is a critical aspect of Product and Analysis Testing, focusing on confirming that products adhere to local and international regulations and standards. This involves rigorous testing and documentation processes to provide evidence of compliance for regulatory approval and market acceptance.

Traceability and Labeling Verification

Traceability and labeling verification ensure that products are accurately labeled with correct information regarding ingredients, nutritional content, and usage instructions. This aspect of testing also involves verifying the traceability of components throughout the supply chain, contributing to transparency and accountability.

Who Choose Airflo Sciences for Product & Analysis Testing

At Airflo Sciences, we prioritize precision and thorough examination in every aspect of product and analysis testing. Our seasoned team of experts brings extensive industry knowledge and a proven track record of delivering results that exceed expectations. We go beyond mere compliance, striving to elevate industry benchmarks and set new standards for quality and safety.

Addition Information

Frequently Asked Questions (FAQs)

Why is product and analysis testing essential for my business?

Product and analysis testing are crucial for ensuring that your products meet quality standards, comply with regulations, and are safe for consumers. Testing provides valuable insights into the composition, performance, and safety of your products, helping you maintain a competitive edge and build trust with your customers.

How often should I conduct product testing for my manufacturing processes?

The frequency of product testing depends on factors such as the nature of your products, industry regulations, and any changes in your manufacturing processes. Generally, regular testing at key stages of production and whenever there are process modifications ensures ongoing quality and compliance.

How does product and analysis testing contribute to regulatory compliance?

Product and analysis testing play a pivotal role in verifying that your products adhere to local and international regulations. Through rigorous testing protocols, you can demonstrate compliance with safety, quality, and labeling standards, reducing the risk of legal issues and ensuring market acceptance.

Can product testing help in identifying areas for process improvement?

Absolutely. Product testing not only evaluates the final product but can also identify inefficiencies or areas for improvement in your manufacturing processes. Analyzing testing results provides valuable data that can be used to optimize production, enhance efficiency, and reduce the likelihood of defects.

How does Airflo Sciences ensure the accuracy of product and analysis testing results?

Airflo Sciences employs state-of-the-art facilities and follows stringent testing protocols to ensure the accuracy and reliability of results. Our team of experienced experts utilizes advanced analytical techniques, and our commitment to quality and precision is reflected in every step of the testing process, providing you with trustworthy and actionable insights.